3D PRINTING & ELECTRONICS VIRTUAL TOUR

3D printing labs give makers a space to learn, explore ideas, test designs and solve for real-life problems using technologies that are quickly becoming an industry standard. This is just one of the many reasons why high schools, colleges and universities all over the world are investing in this endeavor.

Click, Drag, and Zoom to Explore the 360° Virtual Tour

- x2 Weller Soldering stations

- Helping hands

- wire cutters, flush cutters, snippers, etc.

- Various voltmeters

- Magnification lamps

- Screwdrivers and precision bits

- Variable Power Supplies

- Tektronix Oscilloscopes

- Hot Air Rework Station

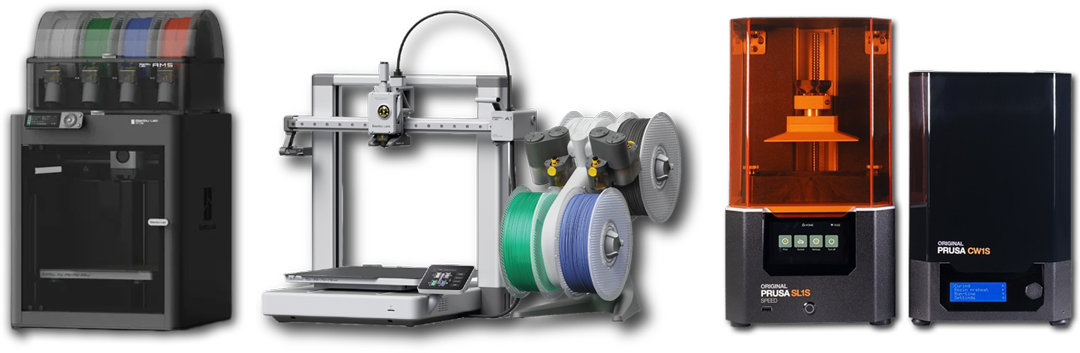

Bambu Lab P1S

Official Documentation is located HERE.

Product Overview HERE

The Bambu Lab P1S is a high-speed, fully enclosed 3D printer engineered for precision, reliability, and ease of use. Designed for both hobbyists and professionals, the P1S offers advanced features that enhance print quality and efficiency.

Key Features & Specifications:

- Printing Technology: Fused Deposition Modeling (FDM)

- Build Volume: 256 × 256 × 256 mm (10.1 × 10.1 × 10.1 in)

- Enclosed Chamber: Improves print quality with temperature-sensitive materials like ABS and Nylon

- Multi-Material Compatibility: Supports PLA, ABS, PETG, TPU, ASA, PC, Nylon, and Carbon/Glass Fiber composites

- Extruder: Direct Drive, all-metal hotend capable of reaching up to 300°C

- Bed Leveling: Automatic mesh bed leveling for hassle-free first layers

- Print Speed: Up to 500 mm/s with an acceleration of 20,000 mm/s²

- Cooling System: Active chamber cooling for better temperature management

- Filament Sensor: Auto-pause on filament runout or breakage

- Noise Level: ~50 dB for quieter operation

- Connectivity: Wi-Fi, SD card, and USB-C

- Slicing Software: Bambu Studio & compatible with third-party slicers (e.g., PrusaSlicer, Cura)

The Bambu Lab P1S is the perfect balance of speed, quality, and ease of use, making it a top choice for makers, engineers, and businesses looking to bring their ideas to life with precision and efficiency.

Bambu Lab A1

Official Documentation is located HERE.

Product Overview HERE

The Bambu Lab A1 is a high-speed, user-friendly 3D printer designed for seamless printing and exceptional reliability. With fully automatic bed leveling, active vibration compensation, and high-speed motion control, the A1 delivers superior print quality with minimal effort. Whether you’re a beginner or a seasoned maker, the A1 makes 3D printing fast, easy, and precise.

Key Features & Specifications:

- Printing Technology: Fused Deposition Modeling (FDM)

- Build Volume: 256 × 256 × 256 mm (10.1 × 10.1 × 10.1 in)

- Extruder Type: Direct Drive for smooth filament feeding

- Max Hotend Temperature: 300°C, compatible with a wide range of materials

- Multi-Material Compatibility: Supports PLA, PETG, TPU, ABS, ASA, and composites with AMS integration

- Bed Leveling: Fully automated mesh bed leveling for perfect first layers

- Print Speed: Up to 500 mm/s, with acceleration up to 10,000 mm/s²

- Motion System: Active Vibration Compensation (XY) for reduced ghosting and improved surface quality

- Cooling System: Dual cooling fans for optimal layer adhesion

- Filament Sensor: Auto-detection of filament runout or breakage

- Noise Level: ~50 dB, optimized for quiet operation

- Connectivity: Wi-Fi, LAN, USB-C, and SD card support

- Slicing Software: Bambu Studio & compatible with third-party slicers (PrusaSlicer, Cura, etc.)

The Bambu Lab A1 is the ultimate blend of speed, precision, and ease of use, making it an excellent choice for hobbyists, educators, and professionals looking to bring their ideas to life with confidence and efficiency.

Prusa SL1S

Official Documentation is located HERE.

Product Overview HERE

The Prusa SL1S is a high-precision MSLA (Masked Stereolithography) 3D printer designed for professionals and makers who require exceptional detail, accuracy, and speed. With its monochrome LCD and powerful UV LED array, the SL1S offers ultra-fast layer curing times and delivers incredibly sharp, high-resolution prints. Perfect for miniatures, dental models, jewelry, prototypes, and engineering applications, the SL1S provides industrial-grade quality in a user-friendly package.

Key Features & Specifications:

- Printing Technology: MSLA (Masked Stereolithography)

- Build Volume: 127 × 80 × 150 mm (5 × 3.1 × 5.9 in)

- LCD Panel: 5.96″ monochrome LCD (2560 × 1620 px) for high-resolution printing

- UV Light Source: Powerful UV LED array with 405nm wavelength for fast curing

- Layer Curing Time: 1.4 – 2.0 seconds per layer (up to 3× faster than previous models)

- Z-Axis Resolution: 0.01 mm (10 microns) for ultra-fine detail

- Resin Compatibility: Works with 405nm UV-sensitive resins, including third-party resins

- Print Speed: Up to 80 mm/h

- Automatic Resin Tank Leveling for easy setup and consistent prints

- Robust Construction: Rigid aluminum frame for enhanced stability and precision

- Touchscreen Interface: 5-inch touchscreen for intuitive controls

- Connectivity: Wi-Fi, LAN, and USB

- Slicing Software: PrusaSlicer (optimized for the SL1S, with support for third-party slicers)

With its fast print speeds, incredible detail, and user-friendly design, the Prusa SL1S is an excellent choice for professionals and enthusiasts looking for high-quality resin prints with minimal hassle.

Creality KR-330

Official Documentation is located HERE.

Product Overview HERE

The Creality KR-330 is a reliable and high-quality FDM 3D printer known for its large build volume, sturdy design, and ease of use. With a 310 × 310 × 400 mm print area, it’s perfect for printing large models, prototypes, and functional parts. The CR-10 features a Bowden-style extruder, an aluminum frame for stability, and precision rollers for smooth movement and accurate prints. It supports multiple materials, including PLA, ABS, PETG, and TPU, making it an excellent choice for both beginners and experienced makers.

Key Features & Specifications:

- Printing Technology: Fused Deposition Modeling (FDM)

- Build Volume: 310 × 310 × 400 mm (12.2 × 12.2 × 15.7 in)

- Extruder Type: Bowden extruder for smoother filament feeding

- Nozzle Temperature: Up to 260°C, compatible with various filament types

- Heated Bed: Supports up to 100°C for improved adhesion with different materials

- Print Accuracy: ±0.1 mm for detailed, high-quality prints

- Print Speed: Up to 180 mm/s (recommended 60 mm/s for best results)

- Filament Compatibility: PLA, ABS, PETG, TPU, and more

- Bed Leveling: Manual leveling with large adjustment knobs for easy calibration

- Frame Construction: Sturdy aluminum frame for reduced vibration and improved stability

- Connectivity: SD card and USB for flexible printing options

- Slicing Software: Compatible with Cura, Simplify3D, and other major slicers

With its large print area, solid construction, and reliable performance, the Creality KR-330 is a popular choice for makers, professionals, and hobbyists looking for an affordable, high-quality 3D printing experience.

We have a modified CR-10 (KR-330) that runs Klipper firmware instead of the typical marlin firmware 3D printers usually use. It is our large FDM printer that can print a maximum size of 12 in by 12 in, or 300mm by 300mm (X/Y), as well as a Z axis of 16in/400mm.

It is up and running however it is still unfinished, you can still use it if you need to. We recommend using this printer for larger models, however you can still print smaller parts if you wish.

We have done some various modifications to it:

- Added an upgraded bed sheet

- Added Bed Leveling hardware with a BL-touch

- Reworked the extruder to use a Petsfang with a direct-drive knock-off bondtech BMG (quality is close if not the exact same as the original)

- Upgraded firmware to Klipper instead of marlin.

- Added various 3d printed additions mainly on the extruder (0.8mm)